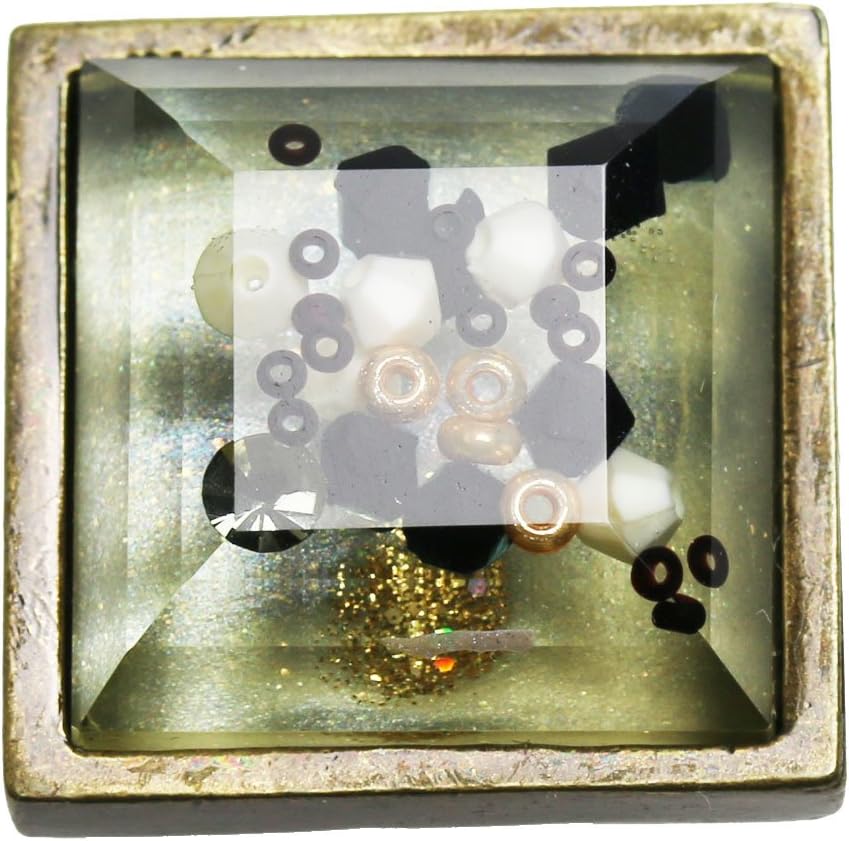

Obidome Simple Japanese Style Decorative Beads Handmade Kimono Decoration

-

Detail

It is an obidome using square resin parts of the "Sesame & Salt Series". It is easy to coordinate with chic shades. You can also use it as a choker through a ribbon or string. Please use it for three to four tenth string cord. *Japanese Kimono accessories "Obidome" refers to an accessory passed through 'Obijime'(a string tied around the waist to fix obi).

Sesame & Salt Series: These are the sesame and salt series. The black beads are the sesame, and the white beads are like salt. Additionally smaller black beads and gold beads accent the series.

These original accessories are made primarily from transparent resin parts with a combination of natural stones, glass beads, felt, and ribbon. One of the same designs looks slightly different because each one is handcrafted. Our concept is to create different designs and pieces that we would want to wear them, and people of all ages can perceive the beauty that lies beyond the accessory itself.

Our History

- September 3rd, 1998 PREMIERE CLASSE store opening.

- September 1st, 1998 "TAMARUSAN" opened in Shibuya.

- July 28th, 2005 Ginza branch opened (Shibuya branch relocation.)

- September 25th, 2016 Ginza branch closed.

- January 1st, 2018 Assembled a workshop, newly opened as "Studio and Shop."

PROFILE

Yukiko Tamaru(Tamaru1go)

Specialty: Assembling and combining parts.

Mikako Tamaru(Tamaru2go)

Specialty: Finding products that look good on our customers.

In making accessories, rarely do we draw our designs on paper beforehand. The reason for this is because we come up with the shapes and designs as we make the accessories. The few times we do draw out the designs prior to making it, is when we design metal parts of photographs or resin parts of main bodies. We ask a specialized metal processing company and stone-polishing craftsmen for their help, and they require designs and specifications. Production mainly divides into metal parts and resin parts.

Producing the resin parts is the most important process for Tamarusan. When resin is made, the first thing we do is name it. This becomes the series name. Hand-drawn pictures are the most common at Tamarusan. We print these designs on either paper or film, according to the texture of the design. In terms of the final product, the main difference is that it will turn out opaque when printed on paper, and translucent when printed on film. When printed on film, the film will reflect a glow the color of the metal fitting on the bottom, or conversely, the color may toned down, so it is important to proceed while observing the resin's compatibility with the metal fittings. Here, a printed piece of paper is used as a template and scissors are used to cut the paper to the size of the finished resin.

The base and the curing agent are mixed together well. Once it is warmed up with hot water, mixing becomes better and curing defects can be prevented. In order to further remove air bubbles, the silicone mold is placed on a hot carpet and warmed in advance. During the winter, work is done with the heating temperature set very high. Furthermore, applying hot air with a dryer makes it easier to remove the air bubbles. Because the temperature is higher in summer, it is easier to operate and there are less mistakes compared to winter. The resin is finally poured into the silicone mold. Because the mold is very small, there are times when the resin overflows or there is not enough. To solve this, a wire is used to even out the amount as a whole. Next, all the materials of the series, such as paper, film, beads, etc. is placed inside. Depending on the seasonal temperature, hardening time is 1 to 3 days.

Metals that are shaped with fire will oxidize, so we will get rid of the dirty portions by soaking in sulfuric acid. From there, it is polished carefully with a metal brush. After this, it is sent to the plating factory. If it is polished cleanly, the resulting plating will also come clean.

Jewelry & Hair Accessories | Womens and Mens

Product Description

Tamarusan's Workshop in Tokyo

About TAMARUSAN

OUR PROCESS

1. Introduction

2. Designing Resin Parts

6. Pouring Resin Into the Mold

9. From Metal Polishing to Plating

-

Customer ReviewsNo comments