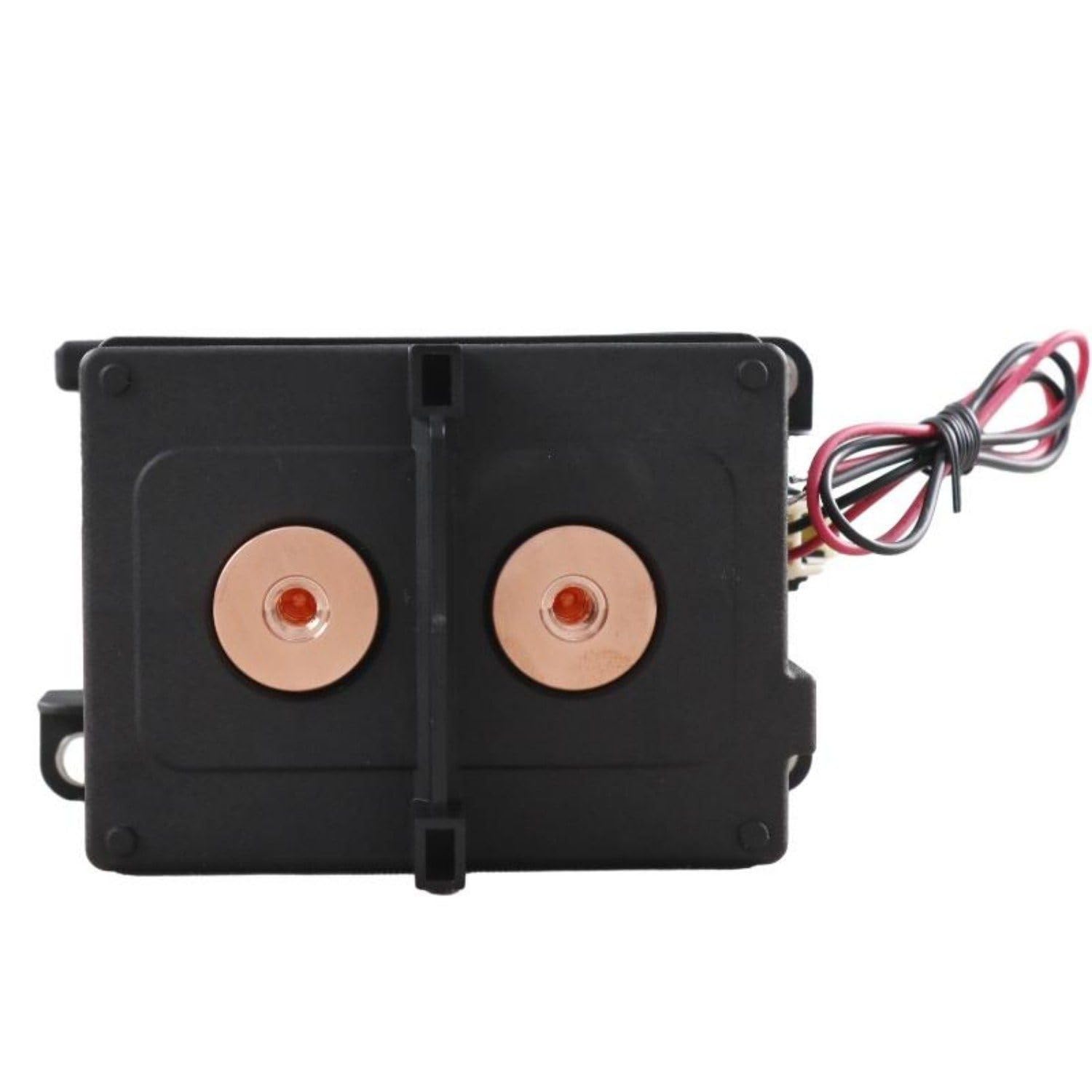

High Voltage DC Relays Contactors Ceramic, 600A 1000Vdc High Voltage DC Relay Contactors, ESS, EV Charging, EV/HEV, PV/Solar Power, Wind Power, UL Listed

【Surety】Ceramic seal structure with magnetic blow-out technology, realize zero arcs, ensure safety and reliability when you using

【Heat-resistant】Carrying current 60

-

Detail

- REACH

- RoHS

- UL 60947-4

- CCC/CE/CB/S Mark

- Ceramic seal structure with magnetic blow-out technology, realize zero arcs, ensure safety and reliability when you using

And I would like to confirm the purpose of “Auxiliary Contact”? In order to monitor if main contact is open or close?

Main contact and auxiliary contact work synchronously;

Auxiliary contact serves as the role of signal transmission, ie.the status of auxiliary contact would reflect whether main contact is open or close.

May I ask, for the coil section with a rated operating power of 6W, is all of this 6W converted into heat?

The coil section generates a heat dissipation of 6W when continuously energised.

Is it sufficient to ensure that the operating temperature of the plastic components does not exceed 130°C?

The temperature of the plastic components may not exceed 130°C, while the low-voltage coil section must not exceed 160°C.

What material is used for the internal copper components?

Oxygen-free copper

Approvals/Standard:

And I would like to confirm the purpose of “Auxiliary Contact”? In order to monitor if main contact is open or close?

May I ask, for the coil section with a rated operating power of 6W, is all of this 6W converted into heat?

Is it sufficient to ensure that the operating temperature of the plastic components does not exceed 130°C?

What material is used for the internal copper components?

-

Customer ReviewsNo comments